Background: Within the school of Mechanical Engineering at Georgia Tech there is one class that strikes fear into the heart of any ME. The class: Creative Decisions and Design, also known as 2110. Every semester teams of 4-5 students are formed to design, test, and build a robot that will compete in a main competition. The course itself is infamous among students for consuming all of your time, as well as drawing out ingenuity though the use of tight equipment, budget, and time restraints. I took this class in the fall of 2020 where I, along with a team of 3 other individuals, were able to rank 2nd out of 40+ teams in the main competition.

Every semester the competition has a different theme, and when I took the class it was the cancelled 2020 Tokyo Olympics. The competition consisted 2 main events in order for teams to score points. The first was an archery evert where the robot was to autonomously launch ping pong balls at a dartboard-like target, with max points being in the center. A similar scoring system was used for the second event, basketball, where the robot was to drive up, release more ping pong balls into a target area, and return to the starting position. All of this was to be completed within a 60 second time limit with no human interaction other than a single button press to set the machine off. If you’d like to learn more about how we did it, there’s more details below.

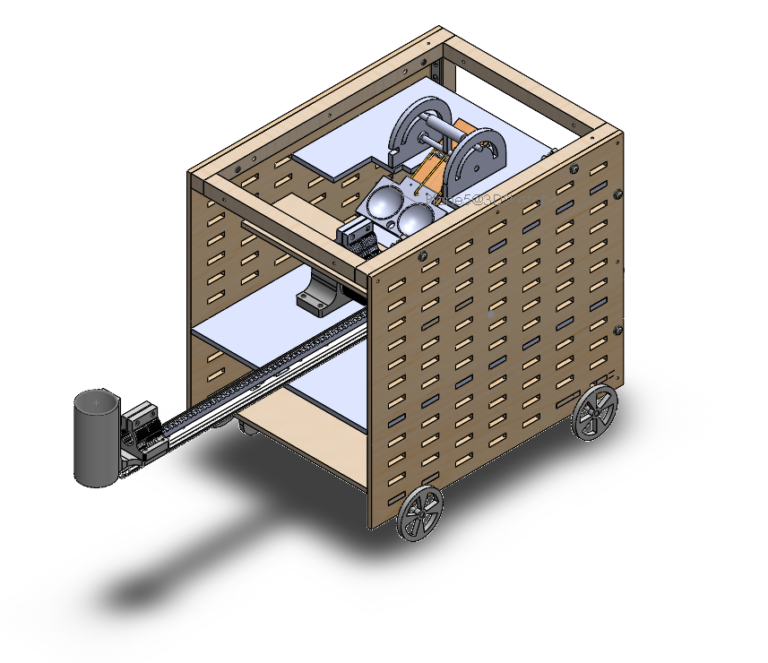

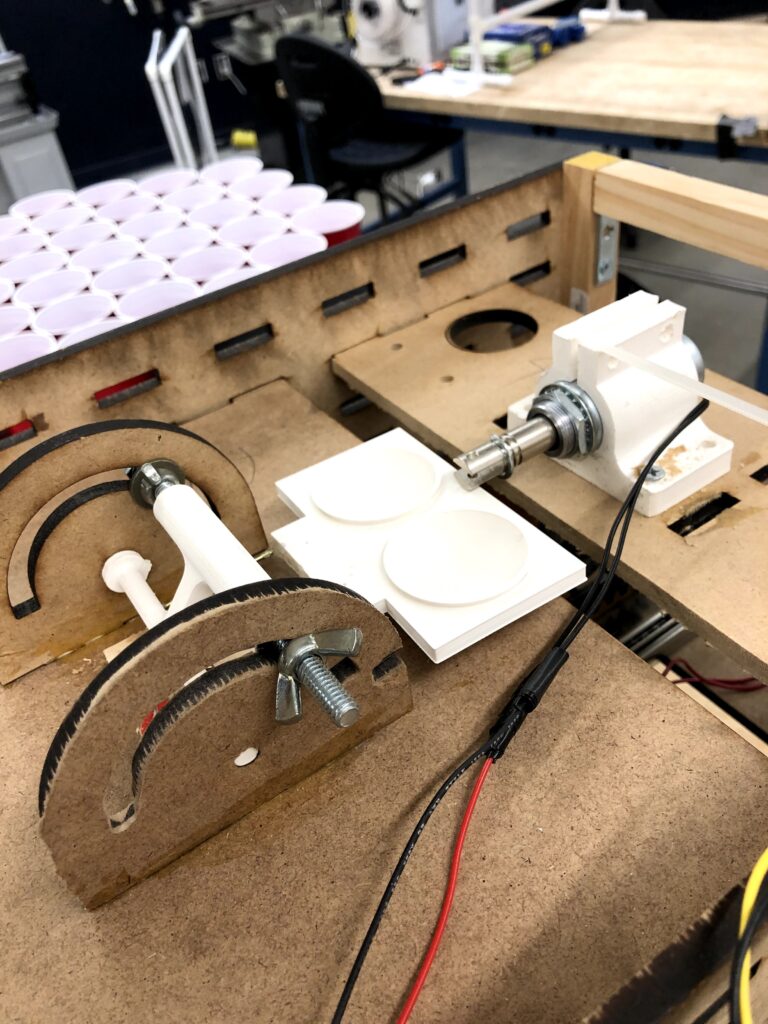

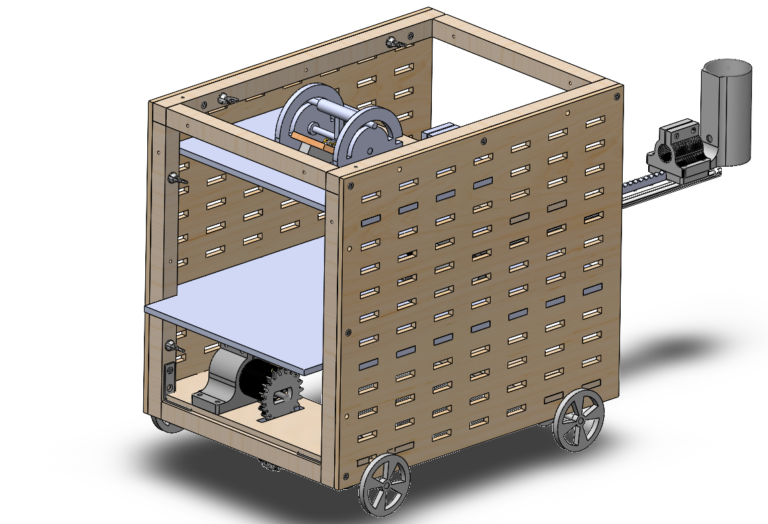

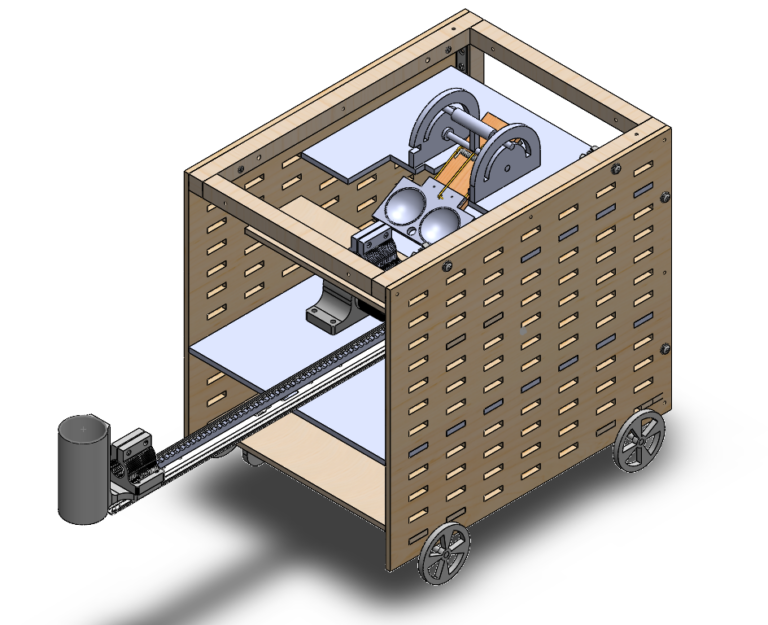

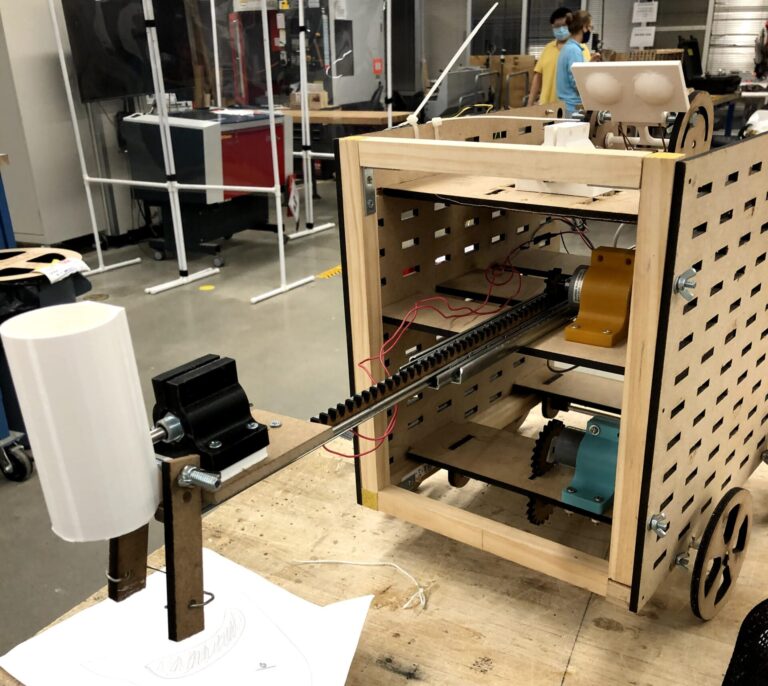

Prior to fabricating any parts, the entirety of the robot was modeled in SolidWorks. As a note this is the third and final iteration of our robot, as we had 2 major design overhauls across the semester to improve our performance. We chose to complete the archery task using one of the allowed mousetraps and a solenoid to activate it. The design of our ping pong ball holder allowed us to save time by not launching each ball individually, giving us more wiggle room for the rest of the run.

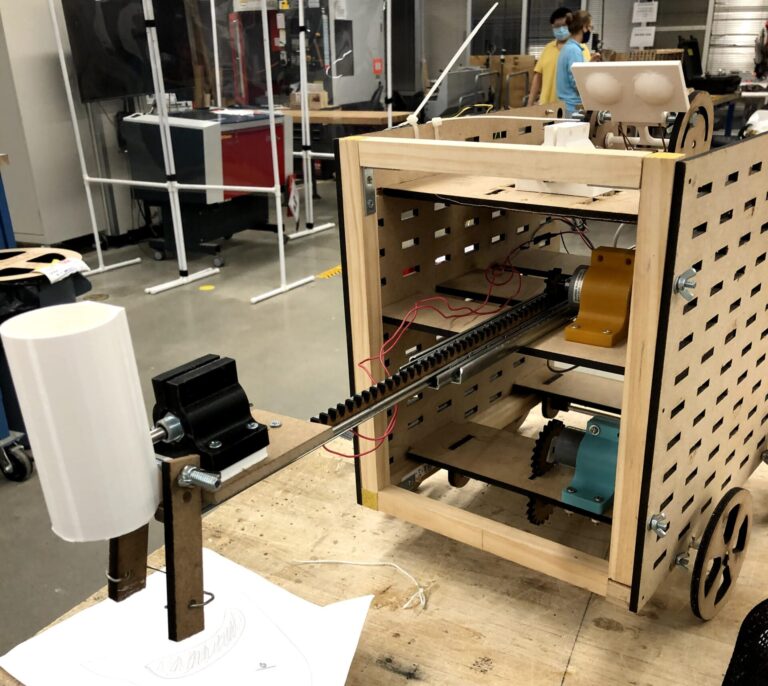

For the basketball event our robot drove up to the target area end extended an arm equipped with a rack and pinion system. The balls were then released using a solenoid that was attached to the end, allowing for them to simply be dropped into the target area. Our machine was consistently able to score max points for this part of the competition, as well a bonus points for picking up an optional ball along the way.

Aside from two aluminum axles joining the wheels and some wooden crossbars, the entirety of this machine was laser-cut or 3D printed. We found that if designed everything in such a way that it required no handmade modifications we could cut down our fabrication and assembly time significantly. This allowed us to test different set-ups and mechanisms with ease and ultimately decide what would give us the best outcome.